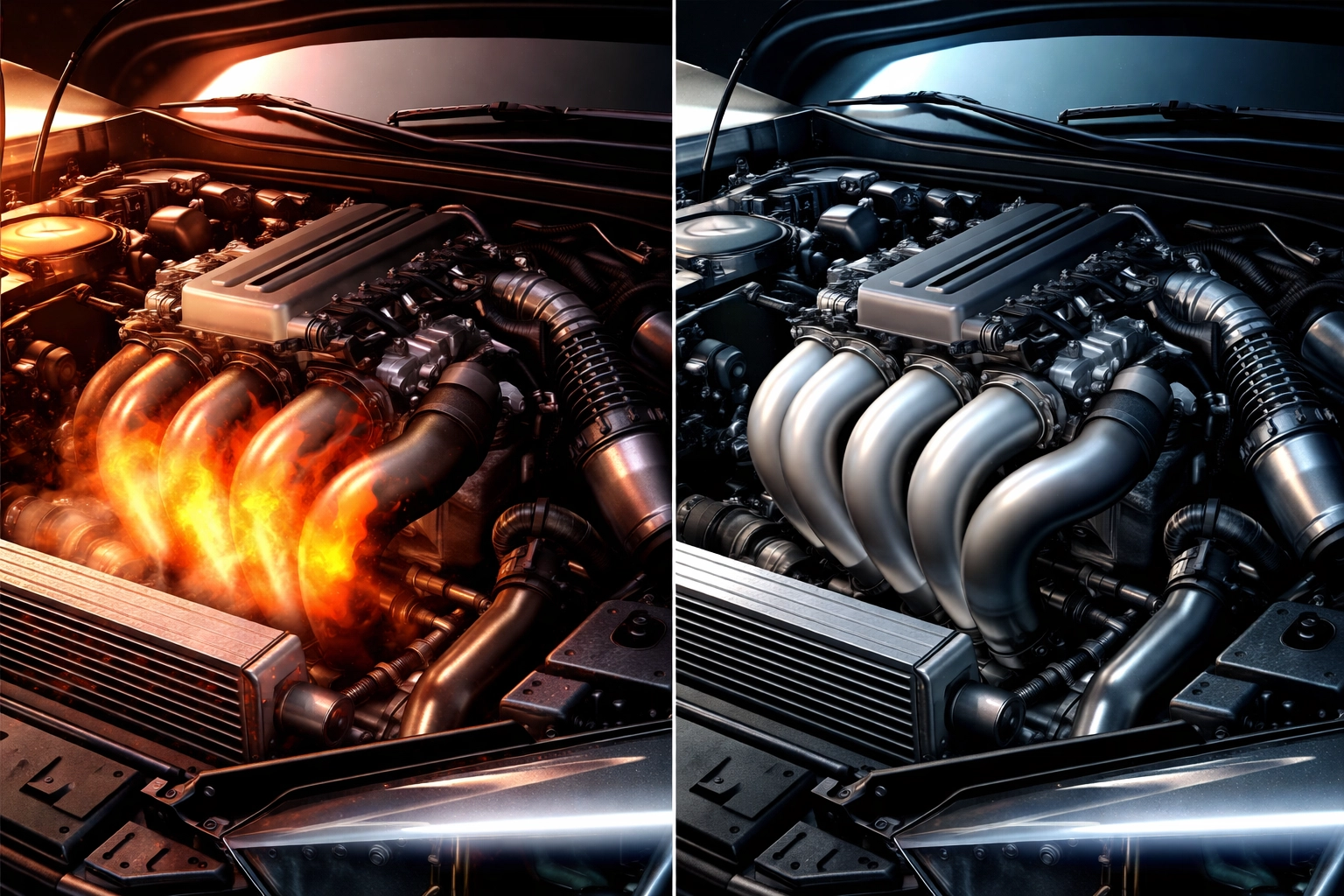

When it comes to protecting and enhancing a vehicle's exhaust system, not every coating can handle the challenge. Exhaust headers, pipes, and manifolds operate at extreme temperatures: sometimes exceeding 1,800°F in turbocharged applications. At those levels, traditional powder coating simply can't keep up. That's where ceramic exhaust coating steps in, offering a unique combination of heat resistance, performance benefits, and head-turning aesthetics that automotive enthusiasts across Santa Cruz, Monterey, Watsonville, and San Jose have come to appreciate.

What Is Ceramic Exhaust Coating?

Ceramic exhaust coating is a specialized high-temperature protective layer applied to exhaust components. Unlike standard paints or powder coatings, ceramic coatings use ceramic nanoparticles to create a heat-resistant barrier that bonds directly to the metal surface.

The coating acts as a poor heat conductor, which might sound like a bad thing at first. However, this property is actually the secret to its effectiveness. By trapping heat inside the exhaust gases rather than allowing it to radiate outward into the engine bay, ceramic coating keeps the surrounding components cooler while improving exhaust flow.

This approach differs significantly from exhaust wraps, which can trap moisture against the metal and deteriorate over time. Ceramic coatings provide permanent protection without the risk of hidden corrosion developing underneath.

Why Powder Coating Won't Work on Exhausts

Powder coating is an excellent finish for many automotive applications. It provides outstanding durability, corrosion resistance, and a wide range of color options. However, standard powder coating has a temperature limit: typically around 400°F to 450°F for continuous exposure.

Exhaust systems regularly operate well beyond these temperatures. Headers connected directly to the engine can easily reach 1,000°F to 1,500°F during normal driving. Performance vehicles and turbocharged engines push those numbers even higher. At these extreme temperatures, traditional powder coating would blister, discolor, and eventually fail.

Ceramic coating is specifically engineered to withstand these punishing conditions. It maintains its integrity, appearance, and protective properties even when subjected to the intense heat cycles that exhaust components experience daily.

For parts that don't get as hot: such as intake manifolds, valve covers, or suspension components: powder coating remains the ideal choice. But for anything in the direct path of exhaust gases, ceramic coating is the way to go.

The Performance Benefits of Ceramic Coating

Beyond simple protection, ceramic exhaust coating delivers real performance improvements that make a noticeable difference under the hood.

Reduced Under-Hood Temperatures

By keeping heat contained within the exhaust system, ceramic coating can reduce surface temperatures by up to 33%. This means less heat radiating into the engine bay, which protects vulnerable plastic components, wiring, and electronic sensors from heat damage.

Lower under-hood temperatures also allow the engine to intake cooler, denser air. Cooler air contains more oxygen molecules per volume, which translates to more efficient combustion and better overall engine performance.

Improved Exhaust Flow and Efficiency

When exhaust gases stay hotter, they move faster. Ceramic coating helps maintain higher exhaust gas velocity, which leads to better exhaust scavenging: the process of pulling spent gases out of the cylinders to make room for fresh air and fuel.

This improved efficiency can result in modest gains in horsepower and torque. For turbocharged vehicles, the benefits are even more pronounced. Hotter, faster-moving exhaust gases spin the turbo more effectively, reducing turbo lag and improving throttle response.

Decreased Back Pressure

By promoting smoother, faster exhaust flow, ceramic coating helps reduce back pressure in the exhaust system. Less back pressure means the engine doesn't have to work as hard to push exhaust gases out, freeing up power that would otherwise be wasted.

Protection Against Corrosion and Rust

Exhaust systems face a constant battle against the elements. Moisture from the environment, condensation from temperature changes, and road salts during winter all attack unprotected metal surfaces. For vehicles in coastal areas like Santa Cruz and Monterey, the salt air adds another layer of corrosive threat.

Ceramic coating seals the metal surface, creating a barrier that prevents oxidation and rust from taking hold. This protection extends the lifespan of expensive headers and exhaust components significantly, making ceramic coating a smart investment for anyone looking to preserve their exhaust system for years to come.

A Unique Look That Lasts

One of the most appealing aspects of ceramic exhaust coating is the finish it provides. Available in matte, gloss, and various colored options, ceramic coating gives exhaust components a sleek, professional appearance that stands out at car shows and meets.

Unlike traditional high-temperature exhaust paints that discolor, chip, and fade after just a few heat cycles, ceramic coating maintains its appearance far longer. The finish resists the yellowing and bronzing that often plagues uncoated or poorly coated exhaust components.

For automotive enthusiasts who take pride in every detail of their build, ceramic coating delivers that show-quality look under the hood or beneath the vehicle. It's a finishing touch that demonstrates attention to detail and a commitment to doing things the right way.

What Components Can Be Ceramic Coated?

Ceramic coating works well on a variety of exhaust components, including:

- Headers and exhaust manifolds – The hottest parts of the exhaust system benefit most from ceramic coating's heat management properties.

- Downpipes – Especially important for turbocharged vehicles where heat retention improves turbo performance.

- Mid-pipes and exhaust pipes – Extended protection throughout the entire exhaust system.

- Heat shields – Additional thermal management for components near the exhaust.

- Turbo housings – Keeping heat contained improves turbo efficiency and protects surrounding components.

Cost Considerations

Ceramic coating for exhaust components typically ranges from approximately $40 to $250 or more, depending on the specific parts being coated and the preparation work required. While this represents an additional investment on top of the exhaust components themselves, the long-term benefits in protection, performance, and appearance make it worthwhile for serious enthusiasts.

Considering the cost of quality headers or a full exhaust system, ceramic coating represents a relatively small percentage of the overall investment while significantly extending the life and performance of those parts.

Serving Santa Cruz, Monterey, Watsonville, and San Jose

At Powder Coat It, automotive enthusiasts throughout the Central Coast and South Bay have access to professional ceramic exhaust coating services. Whether the project involves a classic muscle car restoration, a modern turbocharged build, or anything in between, ceramic coating provides the heat protection and visual appeal that powder coating simply cannot offer at extreme temperatures.

The combination of ceramic coating for high-heat applications and powder coating for everything else means every component on a vehicle can receive the ideal finish for its specific requirements. From brake calipers and suspension parts to valve covers and intake manifolds, the full range of custom coating options is available under one roof.

Ready to Beat the Heat?

For anyone building a performance vehicle or simply looking to protect and enhance their exhaust system, ceramic coating offers a proven solution that delivers real results. The combination of heat management, corrosion protection, performance improvements, and lasting good looks makes it the smart choice for exhaust components.

To learn more about ceramic exhaust coating options or to get started on a project, reach out to the team at Powder Coat It. From headers to full exhaust systems, every component can get the protection it deserves while looking better than ever.

Recent Comments