Powder coating Santa Cruz projects last longer when sandblasting Santa Cruz prep is done first, since clean metal helps the coating bond for a smoother, more durable finish.

When it comes to powder coating in Santa Cruz, the finish quality depends on one critical factor that often gets overlooked: surface preparation. The powder coating process itself creates an incredibly durable finish, but without proper prep work: specifically sandblasting: even the best powder coating can fail prematurely. Chips, peeling, and corrosion can all trace back to inadequate surface preparation.

Understanding why sandblasting matters helps explain why professional powder coating services consistently deliver results that last years longer than DIY or budget alternatives.

What Sandblasting Does for Metal Surfaces

Sandblasting, also known as abrasive blasting, uses high-pressure air to propel abrasive materials against metal surfaces. This process removes rust, old paint, oil, grease, and other contaminants that would prevent powder coating from bonding properly.

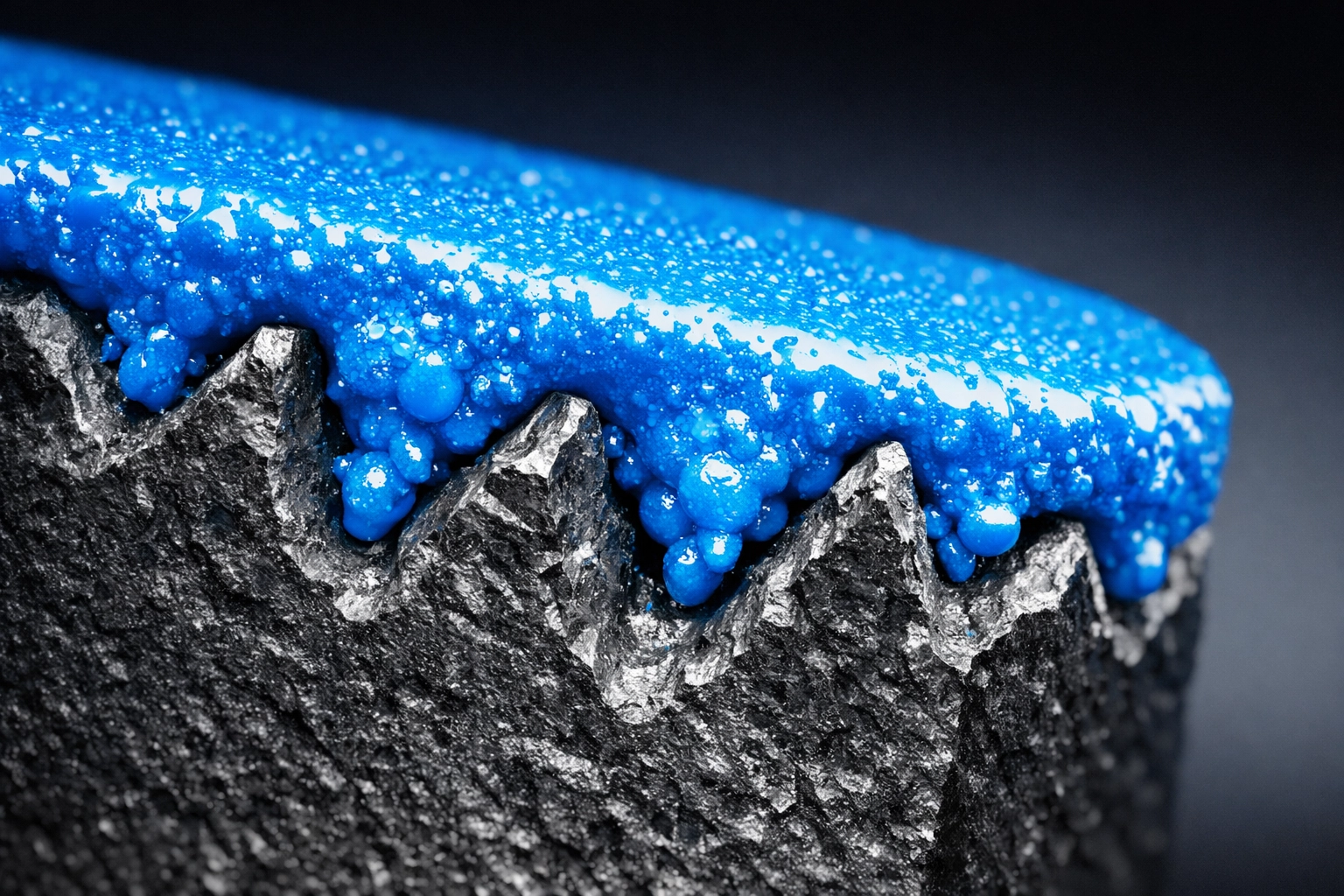

The result is a clean, slightly roughened surface that provides the ideal foundation for powder coating adhesion. The texture created by sandblasting: measured in what's called a "surface profile": gives the powder coating something to grip onto at a microscopic level.

Without this preparation, powder coating essentially sits on top of whatever contaminants exist on the metal. Over time, those contaminants break down, and the coating loses its bond with the base material.

Sandblasting Santa Cruz services remove rust and old coatings so powder coating Santa Cruz finishes bond directly to clean metal for lasting protection.

The Science Behind Surface Preparation and Adhesion

Powder coating relies on two bonding mechanisms: mechanical adhesion and chemical adhesion. Mechanical adhesion occurs when the powder coating flows into the tiny peaks and valleys created by sandblasting, creating a physical lock. Chemical adhesion happens when the coating's resins form molecular bonds with the metal surface.

Both mechanisms require a clean surface. Oil, rust, or old paint creates a barrier that prevents these bonds from forming. Even a thin film of contamination: invisible to the naked eye: can compromise the entire finish.

Temperature also plays a role. During the curing process, powder coating heats to approximately 400 degrees Fahrenheit. If contaminants are present, they can outgas (release trapped gases), creating bubbles, pinholes, or adhesion failures in the finished coating.

Professional sandblasting in Santa Cruz addresses these issues before they become problems, ensuring the powder coating bonds directly to clean metal.

Handling Rusty Parts Versus Fresh Metal

Different surface conditions require different preparation approaches. Rusty automotive parts, old patio furniture, and weathered motorcycle components present unique challenges compared to new or lightly used metal.

These restored patio chairs show how sandblasting Santa Cruz prep supports powder coating Santa Cruz results that look clean, even, and built to handle outdoor wear.

Heavily Rusted or Corroded Parts

Rust removal represents one of the most demanding surface preparation tasks. Surface rust can be removed relatively quickly, but deep pitting and scale require more aggressive abrasive media and longer blasting times.

The sandblasting process removes all visible rust and creates a uniform surface profile. However, rust pitting: the small craters left behind after rust removal: cannot be eliminated through blasting alone. These pits remain visible under powder coating, though the coating still protects the metal from further corrosion.

For parts with extensive rust damage, expectations should be set accordingly. The powder coating will provide excellent protection moving forward, but it cannot reverse existing damage to the metal substrate.

Previously Painted or Coated Parts

Old paint, previous powder coating, or other finishes must be completely removed before applying new powder coating. Sandblasting strips these layers down to bare metal efficiently.

This complete removal is essential because powder coating over old finishes creates a weak point. The new coating can only be as durable as whatever it's bonding to: if the old paint eventually fails, the new powder coating fails with it.

Clean or New Metal

Fresh metal or recently fabricated parts still require sandblasting, though the process is less aggressive. Even new steel typically has a light coating of mill scale (iron oxide that forms during manufacturing) or rust inhibitor that must be removed.

Aluminum parts require special attention. Aluminum forms a thin oxide layer naturally, which must be removed for optimal powder coating adhesion. Using the wrong abrasive media or excessive pressure can damage aluminum, so professional experience matters significantly.

That “surface profile” created by sandblasting Santa Cruz work gives powder coating Santa Cruz finishes a better grip, which helps reduce peeling and early failure.

The Complete Preparation and Coating Process

Professional powder coating bay area facilities that offer both sandblasting and powder coating services provide a streamlined workflow that ensures consistency and quality.

First, parts are inspected and catalogued. Any areas that shouldn't be coated: threaded holes, bearing surfaces, or machined faces: are masked before sandblasting begins.

Next, sandblasting removes all contaminants and creates the proper surface profile. The specific abrasive media, pressure, and technique vary based on the material and condition of the part.

After blasting, parts are immediately moved to a clean environment to prevent flash rusting or contamination. Some metals, particularly steel, can begin forming surface rust within minutes of sandblasting if humidity is high.

Powder coating Santa Cruz color matching is easier with this 600+ color sample wall, and sandblasting Santa Cruz preparation is still what makes any of these finishes bond smoothly and last.

Parts then receive a final cleaning and are preheated before powder coating begins. The electrostatic powder coating process applies a uniform layer of powder, which is then cured in an oven at controlled temperatures. In the Powder Coat It showroom, an amazing color sample wall is available with over 600 colors in stock, so finishes can be seen and touched before a final choice is made. With 600+ colors in stock, a close match can be found for restorations, custom builds, and one-of-a-kind projects without leaving Santa Cruz. No matter which of these 600+ colors is selected, sandblasting is treated as the essential prep step because it removes rust, paint, and residue, then creates a consistent surface profile (a controlled roughness) that supports smooth coverage and long-term adhesion.

This complete process: from sandblasting through final curing: typically takes several days for most parts, though turnaround times vary based on project complexity and current workload.

Why Professional Sandblasting Makes a Difference

DIY sandblasting equipment is readily available, but achieving professional results requires more than just equipment. Experience with different metals, contaminants, and coating requirements determines the quality of the final product.

Professional sandblasting in Santa Cruz facilities use industrial-grade equipment that maintains consistent pressure and abrasive flow. They also have proper ventilation, dust collection, and safety equipment that makes the process safe and environmentally responsible.

Perhaps most importantly, professional services understand how surface preparation affects downstream processes. They know which abrasive media works best for different metals, how to achieve the optimal surface profile for powder coating adhesion, and how to handle specialty materials like aluminum or stainless steel.

Bold shades like this pop when sandblasting Santa Cruz prep creates clean, consistent metal, helping powder coating Santa Cruz colors cure evenly for a unique look.

The cost difference between professional sandblasting and DIY attempts often disappears when factoring in equipment rental, abrasive media costs, and most critically, the risk of having to redo failed powder coating jobs.

What Happens When Surface Prep is Inadequate

Understanding the consequences of poor surface preparation reinforces why this step cannot be skipped or shortcut.

Early failure signs include edge lifting, where powder coating begins peeling at corners or edges within months of application. This occurs when the coating couldn't properly bond to contaminated surfaces.

Undercutting corrosion happens when moisture reaches the metal substrate through a small defect, then spreads laterally beneath the powder coating. Proper sandblasting prevents this by ensuring complete contaminant removal and maximum adhesion.

Blistering occurs when trapped contaminants outgas during the curing process, creating bubbles in the finish. While small blisters might seem merely cosmetic, they represent weak points where moisture can penetrate and cause further problems.

The most frustrating failures are catastrophic delamination events, where large sections of powder coating separate from the part all at once. This typically happens when someone powder coats over old paint or coatings without proper removal.

The Powder Coat It Approach to Surface Preparation

Powder Coat It in Santa Cruz has been providing professional powder coating services since 2010, and proper surface preparation has been a cornerstone of the business from day one.

Every project begins with a thorough inspection to determine the appropriate preparation method. Rusty motorcycle frames, weathered patio furniture, automotive parts with old paint, and pristine new fabrications all receive customized surface preparation.

The facility handles both the sandblasting and powder coating in-house, which eliminates the communication gaps and delays that can occur when these services are separated. This integrated approach also means better quality control: the same professionals who prepare the surface also apply and cure the coating.

For automotive enthusiasts in the powder coating Bay Area who care about both appearance and longevity, this attention to preparation makes a measurable difference in how the finished parts perform over time.

Long-Term Value of Proper Preparation

The primary benefit of professional sandblasting and powder coating is durability. Properly prepared and coated parts can last 20 years or more in normal conditions, and even harsh environments like coastal salt air won't compromise a properly applied powder coating finish for many years.

This longevity translates directly to value. While the upfront cost of professional services exceeds DIY options, the extended service life and elimination of do-over costs makes the investment worthwhile.

Additionally, properly coated parts require minimal maintenance. Unlike painted surfaces that need periodic touch-ups, powder-coated components simply need occasional washing to maintain their appearance.

Contact Information:

Powder Coat It

7000 Soquel Avenue

Santa Cruz, CA 95062

Phone: (831) 435-9558

Website: www.powdercoatitsc.com

Recent Comments